Posted by denny mcdaniels on Oct 17, 2025 in Handgun Cartridge Reloading Info

Loading the 41 Long Colt, content republished from article found at Beaks and Brass, written by Darrell Hartwick.

The 41 COLT was created during the transition from muzzleloaders to cartridge guns, meant that the 41 LC has a unique history. Introduced in 1877, it has more in common with the 22 LR than the 38 Special. The groove diameter of the revolvers chambered for it are listed as being in the range of 0.404 – 0.406”, although the original bullets have a bearing surface that commonly measures 0.410” or slightly more. This became even more complicated when the outside lubricated heel bullet was changed to an inside lubricated bullet that ranged from 0.386 – 0.388” in diameter.

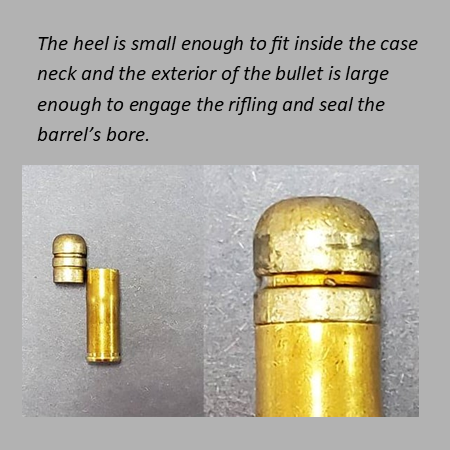

Many of the early cartridges in the transition period, from muzzleloaders to cartridges, used heel bullets, just like the .22 rimfire. Thinking back to our youth, the problem with .22s was the grease picking up dirt from pockets and elsewhere, until companies went with dry lubes or plating the bullets, neither of which were options in the 1880s.

With the change to bullets seated inside the case, protecting the lubricant from the elements, the bullets became under-sized. In order to have them grip the rifling, the bullets were soft and with large hollow cavities in the base. That combined with the strong “bump” that blackpowder provides was enough to expand them so that they could grab the rifling. The 41s reputation for poor accuracy was largely related to trying to get a bullet that was 0.018” too small, to grab the rifling enough to ensure that it was stabilized.

Even with heel type bullets, casting them any harder than about BHN 15 is likely going to work against accuracy unless the bullet diameter matches the groove diameter. An under-size bullet or one that is too hard to bump up to the groove diameter will allow gases to get past it and result in leading due to gas-cutting.

The complication is that the full diameter of a heel bullet needs to be small enough to exit the cylinder without leading it and large enough to fully seal the barrel bore. We supply two bullets for the 41 LC, a 0.410” unsized bullet and one sized to 0.406” that should work well in most revolvers. While a bullet diameter of 0.405 – 0.406” is likely the best, there may be cases when a smaller diameter will be preferred.

In both cases they will need to be lubed after loading, although the 0.406” version has some film lube already on it. The choice of lube will depend on the firearm but Lee’s Liquid Alox is a good starting point (Higginson Powders carry it). Since the bearing surface includes the nose of the bullet, using a liquid lube has the advantage of fully coating the bullet and is easy to apply. Once it dries, the bullets are easy to handle and stay relatively clean.

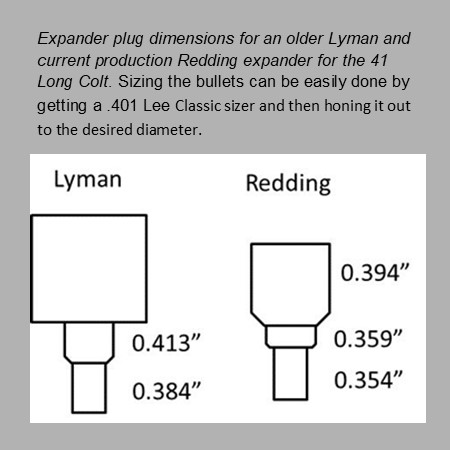

Redding provides regular 7/8-14 dies (#80370, currently a special order item) and Old Guns Canada has a handtool, like the old Lee loader, which is a good option. The other option for dies is to keep a look out on e-bay (or gun stores) for a used die set. Lyman in the past made 7/8-14 dies, although it does not anymore. The diagram below shows the expander plug dimensions for an older Lyman and current production Redding dies. As you can see, the Redding expander would not likely require any crimping, other than perhaps to iron out any belling of the case mouth. In the case of the Lyman expander crimping is more likely going to be required.